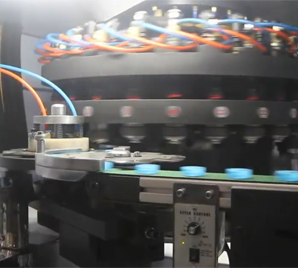

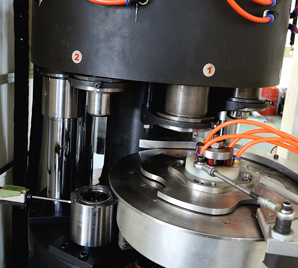

Maisheng full automatic high speed cap compression moulding machine adopts hydraulic clamping principle, technic of rapid prototyping and mould release of low pressure, etc.to manufacture with continuous totation, widely used in the manufacture of bottle caps of carbonated beverage, mineral spring water, pharmaceutical products.

Maisheng cap compression molding machinne adopts continuous compression process to produce caps .Granular plastic raw material which is fed via the hopper,plasticized with tempertature ,and then extruede from the discharge outlet of the extruder ,cut with the cutting tray,uniformly distributed into each mold cavity and finally shaped by mold compression .